Having the right quantities of the appropriate blood products at the right time is a critical requirement of timely, and therefore safe, transfusion care. Generally speaking, the larger and more complex the hospital transfusion service, the more challenging inventory management becomes. Fortunately, there are increasingly sophisticated communication tools available to support the coordination of hospital orders and blood center deliveries. As an added bonus, these blood ordering platforms may also yield cost and resource savings.

If routinely stocking blood at your facility still involves numerous telephone conversations or multiple faxes that are augmented with pens, paper, and clipboards for dutiful note-taking, there are several technology upgrades on the market that can streamline your processes, tighten your documentation, and save you effort. Tracking features that plot the progress of shipments may also reduce the anxiety that often attends the time-honored blood banking tradition of watchful waiting for an urgently anticipated courier. Over the last decade automated blood ordering has become the common standard of service that blood centers offer to their client hospitals.

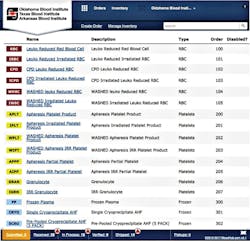

Easy implementation and use are among the most gratifying aspects of these web-based information technologies. What the hospital lab needs is a reliable internet access and a recent version web browser. After the fashion of other forms of online shopping portals, there are “carts” that can be filled with items selected from intuitively navigable menus. Because of this format, lab staff can become readily familiar with the full range of available features and options and can therefore customize an order to meet the particular needs of physicians and patients.

As both an aid to communication and convenient audit trail, each entry can be traced to its creator or author. Special requests or instructions are documented and updated in an easily referenced, typewritten attachment to the original order. This reduces the risk of miscommunication, especially by newer staff who may not be fully familiar with the myriad of specialized terms used in transfusion medicine. Recurring, standing orders can also be programed as a reliable underpinning for the routine flow of blood supplies needed to support the hospital’s regular needs. Because of the clear display of pending order status, handoffs between shifts at the hospitals and blood centers can become more effective. Similarly, the chances for an inadvertent duplicate order decrease.

Another user-friendly aspect of such platforms is their reliability. Benefitting from years of design evolution and robust software, today’s platforms suffer few “crashes” and only occasional planned down times for maintenance and upgrades. Automatic data back-up is a standard feature that speeds recovery time and offers operation resilience. Naturally, traditional methods of ordering (e.g., phone calls, faxes, or emails) usually remain in place as contingencies for any such service interruptions. However, if the disruption is caused by a network failure at the hospital, logging on via smartphone or tablet is usually the primary back-up option.

Via customizable reports, there is ample opportunity to “work smarter” by tracking and analyzing utilization data and performance metrics. Patterns of STAT and urgent ordering can be mined to reduce shipping urgency and, often, associated fees. Excessive handling and accessioning expenses (e.g., typing incoming red blood cell units, packing and unpacking shipments, etc.) can be cut by not overstocking and returning inventory. There is ample capacity built in to drill down by day of the week, shift, and employee. Patterns for different product types can also be uncovered.

The relationship with suppliers is open to better characterization and review, too. Blood centers can be measured by their turnaround times and successful fill rates for original orders and subsequent “backfills.” Visibility by individual product variety and blood group can focus this accountability in chronic problem areas, such as providing O negative red blood cells, apheresis platelets, and AB plasma. As an added benefit, this level of scrutiny helps establish for inspectors and regulators that quality measures are in place for the blood supply, an absolutely critical control point for the safe operation of the hospital.

For hospital systems, the analytics can span all of their hospitals and blood centers, offering the added power of benchmarking and best practice identification. This may also be an avenue for standardizing transfusion product codes and definitions to enhance data applicability and comparability. In an era when supply chain managers are focused on value for their purchases, offering consolidated, accessible information empowers informed and effective decision making.

As attractive as current technologies are for laboratorians and their blood center partners, future enhancements promise even greater benefits. Aggregated usage data mapped across the blood center’s entire distribution network will prompt proactive donor recruitment campaigns tailored to avert emerging shortages. Within the hospital, interfaces with LIS systems hold the promise of tighter inventory management of product outdates and returns, reflexive replacement of issued units, and experiential setting of stock levels. Workflow monitoring will enable hospital and blood center staffing schedules to match peaks and troughs in the typical daily and weekly task burdens. Upgrades that employ dynamic routing logic will eliminate costs in transportation by identifying the most efficient pathways to fill multiple, concurrent deliveries. Integration with financial software will enhance billing accuracy and minimize the time and tedium of invoice reconciliation and adjustments.

Enhancements in information technology and communication have a strong record of success for improving care and streamlining operations in hospitals and laboratories. The barriers to entry are low and the returns on investment are high when one considers an automated blood ordering platform. The time for embracing this innovation is today—if the moment has not already been seized by your transfusion service.

John Armitage, MD, is a clinical pathologist and serves as CEO of the Oklahoma Blood Institute (OBI).

William J. Martin III serves as Technical Operations Project Manager for OBI, working with all Technical Operations departments.