With the ongoing

public focus on medical errors, histology and cytology laboratories

around the country likely are tired of the continued pressure to respond

to address this issue. Improvement of process flow is not a new topic.

Medical laboratories have always tried to operate efficiently, and any

laboratory errors have been scrutinized by lab professionals with an eye

toward systematic elimination. Nonetheless, clinical laboratories,

driven by Six Sigma and LEAN analyses, have made valiant attempts in

recent times, once again, to improve their processes and reduce errors

with workflow changes. Steps have been counted, tables have been

rearranged, and new methods have been developed.

What has changed recently is the importance and

the impact of current information systems on the medical laboratory's

goals. When it comes to the histology and cytology departments,

traditionally, information systems' ability to support efficient process

workflow has been hampered — not due to lack of desire by vendors.

Rather, the designers of information systems have had to wait for the

appropriate tools to be developed, and those tools are now available for

widespread adoption.

The brilliance of bar coding in histology

Chief among the recently available tool set is the widespread availability

of bar-coded cassettes in the histology laboratory. The challenge in the

development of these cassettes was the requirement for a bar code small

enough to print on the edge of the cassette but with enough room for

human-readable information. The imprinted information had to withstand

processors, wax, scraping, and other types of mechanical manipulation.

Labelers are now available from General Data, Thermo, Leica, and Triangle

Biomedical Sciences, to name a few, and these allow information systems to

automatically generate cassettes with bar-code and specimen information

printed on the edge of the cassette. This new process yields a significant

decrease in mislabeled cassettes, while generating more labeled cassettes

per hour than any manual process could achieve. From a lab professional's

perspective, far fewer hand cramps occur because a histotechnologist no

longer has to spend hours trying to write legibly on a cassette's small

surface.

Similarly, the ability now exists to print slides

or slide labels with bar codes; vendors such as Zebra and Thermo come to

mind. Coupled with bar-coded cassettes, the histotechnologist can scan a

cassette and have the computer system generate the slide or labels that

are relevant for a specific block. Again, this reduces legibility errors

and significantly increases throughput. Imagine the difference between

writing a patient name, case number, slide, and block identifier on

every slide compared to simply scanning a cassette.

With this critical bar-coding step for workflow

improvement, the most significant materials of the laboratory can be

tracked. In order to improve a process, the process has to be quantified

or measured. With bar codes on cassettes and slides, information systems

can now track the time spent at each step of processing, be it at the

grossing station, stainers, or, finally, at the pathologist's desk. With

this information in hand, medical laboratories can adjust and fine-tune

their operations to meet specific needs and requirements.

Bar coding improves cytology's workflow, too

Not to be left out, the cytology department

is also taking full advantage of the recent tools available to

information-system vendors. As with histology, bar-coded slides are

automatically generated by information systems. In some cases, these

slides or slide labels are generated at order entry, while other

vendors generate the slide or labels upon scanning the specimen

vial. The same gains enjoyed by the histology department are now

available in cytology. Materials are tracked throughout the medical

lab, thus reducing the opportunity for lost specimens.

Pap smears contribute a significant percentage of

the total volume of cases processed by most cytology departments. For

larger departments, the use of automated imaging is becoming more

commonplace. Today, information systems generate either bar-coded slides

or labels that these imagers can use to identify the unique sample. In

some instances, optical character recognition, or OCR, identifiers are

placed on the slide or label to facilitate that process.

In recent years, the advent of human

papillomavirus (HPV) testing has become routine; and in certain

situations, HPV testing is even supplanting the traditional Pap smear.

Here again, information systems have developed new mechanisms to

automatically order HPV testing based on an assortment of ordering

criteria. Initially, HPV tests were reflexively ordered via information

systems based only on an abnormal Pap-smear result. More recently,

information systems have evolved to a rules-based ordering mechanism

whereby HPV test orders are placed based on many different factors:

patient age, previous HPV result, and ordering clinician preference —

just a few examples of the factors considered by newer ordering

algorithms.

The histology and cytology laboratories are

busier than they have ever been. Increasing focus on process flow and

improved efficiencies has become the new rallying cry. To assist in

their effort, leading-edge information system vendors have adopted newly

minted products to assist laboratories. By taking advantage of the best

that these information systems have to offer, the histology and cytology

departments can keep abreast of current trends and stay at the forefront

of demand.

Michael Milhalik works as vice president of

marketing and sales with Pathview Systems in Anna, TX.

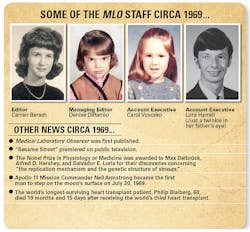

“Congratulations to MLO on 40 years of providing timely

information to all of us in clinical laboratories. We are richer by far

for this and look forward to the next 40.” — Leland B. Baskin, MD,

MS, F(CAP), F(ACB), Division Head, General Laboratory, Calgary

Laboratory Services, Calgary, AB, Canada, and member of MLO

editorial advisory board.