2024 lab management best practices trend back to the basics

The results of the 2024 Medical Laboratory Observer (MLO) State of the Industry (SOI) Survey on Lab Management Best Practices reveal how many lab professionals are turning to fundamental practices and priorities to make operational, clinical and financial improvements – from a focus on staff career development to strengthening supplier relationships.

MLO gathered responses from nearly 100 clinical laboratory professionals with 42% of respondents in director, manager, administrator, or supervisor positions, and most employed by hospitals (61%). Respondents spanned labs of different sizes and testing volumes.

The survey results provide insights into best practices around controlling costs, optimizing contracts, capturing reimbursements, managing supplies, implementing technology solutions, navigating staffing shortages, and improving the quality and efficiency of testing.

Four key findings:

· Staffing: More labs are leveraging career ladder development and flexible scheduling to attract and retain staff members, while fewer are offering financial incentives.

· Technology: Labs are looking for technology to improve quality/reduce costs and/or cover broken/older equipment when prioritizing capital investments.

· Supply chain: The two most leveraged best practices to improve inventory control and consumable supply costs are the evaluation of inventory levels for basic supplies, such as assays and controls/reagents, and the development of supply utilization tracking and record keeping.

· Contracting: More lab professionals are developing good relationships with supplier support personnel to streamline contracting processes, while fewer are working with supply chain management on group purchasing organization (GPO) contracts.

Alongside the quantitative data, the article presents insights from Fontanilla Manliswe, MLS(ASCPi), MSHS(CLS), Director of Laboratory Services, Northern Nevada Medical Center (NNMC); Ryan Stephens, Roche Group Marketing Manager, Automation; and Dan Young, Medline Senior Director, Supply Chain Optimization.

Staffing

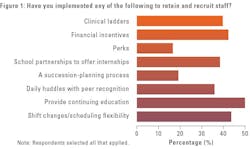

Staffing remains top of mind among lab leaders. When asked which measures they implement to recruit and retain staff, half of survey respondents (50%) said they provide continuing education, which was the same percentage of respondents as last year. Slightly more lab professionals said they are facilitating shift changes to offer employees scheduling flexibility (12-hour shifts, weekends, etc.), at 44%, up from 40% in 2023.

Career development support is growing in strategic value. Lab professionals reporting they have developed career ladders (structure to encourage professional development, such as from novice to expert) increased 10%, at 40%, up from 30% in 2023.

The percentage of labs that partner with local colleges and technical schools to offer internships remained the same as last year at 38%, while those holding daily huddles with peer recognition dropped only slightly, at 36% in 2024, compared with 38% last year.

Though still high in the rankings, labs offering financial incentives (sign-on bonuses, merit allowances, retention bonuses) to improve staff recruitment and retainment, dropped by more than 10%, at 42% compared with 53% in 2023. Succession-planning processes, where labs offer additional responsibilities to top performers and measure their results, dropped by 10%, at 19%, down from 29% last year.

Lowest in the rankings were labs offering perks, such as free parking, onsite gym, onsite day care, public transportation cost reimbursement, with 17% of respondents reporting their labs use this method to retain and recruit staff, down from 21% in 2023.

Costs and reimbursement

Regarding steps they have taken to ensure reimbursement covers their costs, around half of respondents reported they have standardized instrumentation workflows and checklists (58% up from 52% in 2023), created standard lab processes and staff education materials (56% up from 53% in 2023), and incorporated IT solutions to reduce human error (50% up from 40% in 2023).

Use of analyzers that provide walkaway testing to reduce staffing and full-time employee (FTE) hours was also high up on the list at 41% of respondents (up from 39% in 2023). There was a 13% jump in those that have incorporated IT solutions to help keep current with regulations (37% in 2024, up from 24% in 2023). Over a third of respondents (36%) reported using processes to review savings opportunities, such as evaluating analyzers on a regular schedule (up from 28% in 2023).

Approximate one-quarter of lab professionals (26%) reporting bringing health screening tests in house (up from 19% in 2023) and/or implementing ongoing waste and efficiency studies to find potential savings in overhead (24%, up from 19% in 2023). Additionally, 21% reported implementing ongoing efforts to reduce coding frustrations and modifications (up from 18% in 2023).

Nearly half (45%) of lab professionals surveyed report being able to track whether reimbursement covers their costs. Of those facing roadblocks with tracking:

· 34% reported not enough staff time (up from 32% in 2023)

· 27% not having software to automate tracking/analysis of costs (down from 35% in 2023)

· 24% lack of interoperability between their laboratory information system (LIS) and revenue cycle management software (down from 34% in 2023)

· 6% not having enough barcoded testing supplies (down from 7% in 2023)

Technology and training

This year, the top two priorities for technology capital investments were reported to be technology needed to improve quality/reduce costs (62% in 2024, down from 70% in 2023), and technology needed to cover broken/older equipment (60% in 2024, up from 38% in 2023).

Next in terms of investment priorities were technology needed to cover staff shortages with automated equipment (40% in 2024, down from 52% in 2023), and technology needed to remain competitive (35% in 2024, down from 42% in 2023).

“Labs of all sizes are adopting automation and digital solutions to simplify their lab operations,” said Ryan Stephens, Roche Group Marketing Manager, Automation. “They’re seeking to improve laboratory efficiency by utilizing fully automated solutions that can be customized to meet their current and future needs.”

“These automated solutions help solve many challenges that labs are facing, including budget constraints and staffing shortages,” Stephens added. “Additionally, the advancement in digital solutions allow laboratories the ability to capitalize on the data that they generate to better support their patient populations.”

To support new technology adoption, 43% of laboratory professionals surveyed reported analyzing workflow processes for proper space planning (down from 55% in 2023), 37% involving the IT department early in the process (down from 51% in 2023), and 21% designating a project manager to coordinate short- and long-term planning and implementation with the vendor (down from 23% in 2023).

Nassreen Fontanilla Manliswe, MLS(ASCPi), MSHS(CLS), Director of Laboratory Services, Northern Nevada Medical Center (NNMC), commented on her experience from her previous workplace leading the consolidation of chemistry and special chemistry instruments from seven down to two integrated lines for a 900-bed hospital.

“While the instrument vendor offered a great deal of support, it was critical for our lab to have a point person who could champion and lead the transition,” she said. “At the time we did not have a lab director at that facility and my lab manager’s background was micro, so I became that point person and it was a great learning opportunity.”

Fontanilla Manliswe noted that even if there are clear benefits to implementing new technology, lab staff are likely to resist change because of the learning curve and having to support multiple systems until the transition to the new platform is completed. She stated, “my role at that time was to acknowledge to the team that there were challenges but emphasize the positive aspects of the change and ensure them that we could manage it successfully.”

Among lab professionals surveyed this year, more than half reported creation of train-the-trainer models as a best practice to train staff on new software (54% down from 57% in 2023), and/or have created standard workflows for all lab employees (52% down from 56% in 2023).

About one-third of respondents said someone in their lab received LIS training to develop an in-house expert (32%, up from 31% in 2023) and/or participated in vendor-hosted in-house or online training (30% down from 37% in 2023).

Nearly one-quarter of those surveyed have developed mandatory training led by the IT department for new lab employees (24% up from 20% in 2023), and 22% reported the development of lunch-and-learn training sessions (up from 15% in 2023).

During her lab’s chemistry instrumentation consolidation, Fontanilla Manliswe sent her staff to vendor training while developing her own knowledge of the technology so that she could serve as a “super user” to support them through the transition and post-implementation.

“At some point, an instrument can go down for any reason and that changes the entire mood for the day,” she stated. “Serving as the single point person and super user, my staff knew I was their lifeline – they could call me, and I would work with them to resolve the issue. And if I didn’t know the answer to a question, I could at least direct them to someone who could help them.”

Another best practice for staff training on new technology that Fontanilla Manliswe employed was customizing standard operating procedure (SOP) to align with her lab’s specific needs.

“The vendor provided SOP templates for the analyzers and instrumentation, but they didn’t necessarily apply to how we use the platforms. I turned to my team members for their input when developing our SOPs so they matched what they were actually doing in the lab in terms of workflows and tasks. This helped tremendously with implementation because when we went live, my team already knew how to follow the SOPs because the information came from them rather than a template.”

Test quality and efficiency

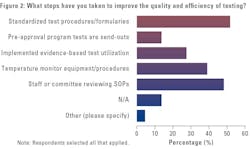

With regards to steps taken to improve the quality and efficiency of testing, 52% of lab professionals reported using standardized test ordering procedures and formularies (down from 63% in 2023), 48% have implemented staff and committee review standard operating procedures (SOP), and 39% have evaluated temperature monitoring equipment and procedures (down from 51% in 2023).

Other best practices for improved testing quality and safety include implementing evidence-based test utilization backed by data (28% in 2024, up from 27% in 2023) and implementing a pre-approval program for tests that are “send-outs” (14% in 2024, down from 22% in 2023).

Supply chain

Having access to the right supplies at the right times is critical to lab management. While 36% of survey respondents reported having no supply chain issues, the remaining 64% cited best practices they are leveraging to mitigate issues that arise.

Topping the list of best practices is implementation of standing orders (instead of just in time) for crucial supplies at 37%, down from 58% in 2023. Next, utilization of multiple testing platforms at 30%, down from 44% last year. Lab professionals reporting the switch from disposable to reusable personal protective equipment (PPE), such as lab coats, increased, at 20%, up from 14%.

There was a big drop in survey respondents who reported working with state public health officials to gain access to needed testing supplies, at 16%, down from 31%. Those using laboratory-developed tests to address supply-chain issues changed little, 13% in 2024 compared with 14% in 2023.

In general, supply shortages have eased according to Fontanilla Manliswe, but her lab and others were surprised by the intensity of the increase in SARS-CoV-2 testing volume during December 2023-January 2024. She stated:

“We use a 4-plex assay and we expected an increase but did not expect the level of the increase in need for COVID-testing earlier this year. I monitor supplies almost every other day and found each of our locations – labs in our two main hospitals and two freestanding ERs – were each consuming one box per day during December and January. It was not just our lab that was understocked; it happened all over. Labs were on allocation until February.”

When asked what steps they have taken to improve inventory control and consumable supply costs, inventory evaluation of basic supplies, such as assays and controls/reagents, garnered the highest percentage of responses, at 69% (down from 74% in 2023). Nearly half of respondents (46%) have developed supply utilization tracking and record keeping (up from 39% in 2023).

Close to one-quarter (24%) of lab processionals report having worked with other members of their organizations, such as the chief medical officer (CMO) and physicians, to standardize test ordering throughout the organization (up from 20% in 2023). Among those surveyed, 20% have secured access to electronic inventory tracking from the supply chain/materials management department (up from 18% in 2023) and 19% have developed ongoing review comparing supply reports to the number of invoiced tests (down from 20% in 2023).

Fewer respondents report having implemented lease agreements that do not include volume commitments, compared with last year (14% in 2024, down from 18% in 2023) and/or implemented vendor-managed ordering (12% in 2024, down from 15% in 2023). An additional 12% indicated tasks related to inventory control and consumable supply costs are handled by a different organization/location.

Fontanilla Manliswe offered her best practice in lab supply management; making supply monitoring everyone’s responsibility, not just that of the lab manager and department leads. She explained how empowering technologists to monitor supply levels not only helps a lab avoid stockouts, but also helps technologists grow in their responsibilities and experience. She explained how this works:

“We have partnered one or two technologists with leads of each department based on their interests – for instance, one tech might want to help with hematology or chemistry, while another is interested in supporting the blood bank. The techs are responsible for monitoring supplies for their assigned department. Let’s say there are only two boxes left of a certain product. It is the tech’s responsibility to alert me, the manager, or the lead to the low levels so we can get the product ordered before we run out.”

“Lab techs typically have few opportunities for career progression,” Fontanilla Manliswe added. “Simple tasks like supply management can help techs grow toward the possibility of progressing to leads. It also gives them the opportunity to decide whether they really want that level of responsibility.”

Contracting

Turning to strategies to streamline contracting processes, 61% of lab professionals report developing good relationships with supplier support personnel to access training and product optimization suggestions, up from 48% in 2023.

The percentage of survey participants who reported working with supply chain management on group purchasing organization (GPO) contracts for additional savings was still high on the list at 55%, but down from 65% in 2023. Fewer lab professionals say they are signing longer contracts (for example, 7 years instead of 1–3 years), at 16%, down from 20% last year.

Ongoing reviews of reference lab costs and contracts continues to be a popular strategy to streamline contracting processes, with 39% of respondents reporting they have implemented this best practice, the same as last year.

Dan Young, Medline Senior Director, Supply Chain Optimization, noted how laboratories can apply lessons learned and best practices from medical/surgical supply management to improve their own supply chain performance. He stated:

“We are seeing some health systems recognize there are ways to apply supply chain best practices they have developed in the acute care space to other areas of spend, in this case labs. It helps the labs do more tests and increase their throughput and efficiency.”

“From a health system leadership standpoint, the more spend you can have under management, the more consistent methodologies and systems can be applied to manage the movement of goods and control of the dollars, and the greater the benefit to the organization overall,” Young added. “I encourage lab managers to ask how they can fit more within their health system’s central supply chain channel so some of the supply management workload can be shifted off their desks. At the same time, centralization can help supply chain leaders generate more savings.”

To alleviate lab teams of supply management, Young also encourages decisions makers to consider vendor managed inventory programs but notes the importance of maintaining visibility-into and control over supply data when taking this approach, stating:

“Having your business partners come in and take care of your inventory is a great way to alleviate some headaches but be sure you keep your arms around the data, including what’s being put into inventory and what you’re consuming.”

Evaluating lab automation solutions

Ryan Stephens, Roche Group Marketing Manager, Automation, offered lab professionals these questions to ask when evaluating technology solutions to automate processes:

· How does this automation platform help simplify our day-to-day laboratory operations?

· How does the automation solution adjust to the changing needs of our lab throughout the day?

· Can the automation solution be scaled after implementation to meet our future growth?

· Does the automation solution offer the flexibility to automate multiple disciplines?

· What pre-analytical sample integrity checks are included in the solution?

· How flexible is the automation solution to our lab space restraints? Does it have the ability to create walkways in the lab without reducing our throughput?

· How do you continuously monitor the efficiency of the automation solution?

About the Author

Kara Nadeau

has 20+ years of experience as a healthcare/medical/technology writer, having served medical device and pharmaceutical manufacturers, healthcare facilities, software and service providers, non-profit organizations and industry associations.